Dear Maker Abby –

I have a rod holding up my window shades that has several broken pieces I’d like to replace. The shade doesn’t really work right now because of these broken parts.

Unfortunately, I can’t buy replacement parts so I was hoping I could have them copied and fabricated somehow. I am a prosthodontist and am familiar with 3D scanning and printing. I looked online and found that I could have the part 3D scanned, but it would cost more than $300 to do so. Then I’d still have to send it out to be printed.

My only other option is to replace the entire system, which would be both expensive and non-eco-friendly.

Can you help teach me how to make these replacement parts at a reasonable cost?

Gary Wetreich, Weston

Dear Gary –

At the Art & Innovation Center, we have a 3D scanner and 3D printers available for use by the public.

You can bring in the part and I will show you how to scan it. It will cost you $5 to use our equipment each time you come during Open Maker Hours. Once your part has been scanned, you can sign up for 3D printing certification to learn everything you need to print these parts yourself. You even have your choice of color to print the new part.

Open Maker Hours are Wednesdays from 1 – 8 and Saturdays from 1 – 4. Let’s set up a time to work on this!

Abby, Art & Innovation Center Makerspace Technologist

Resolved:

Gary and Abby worked together to get a replacement part made. Abby showed Gary the 3D scanner and how it can create a 3D file. Gary decided to make several additional pieces in case he needed more in the future.

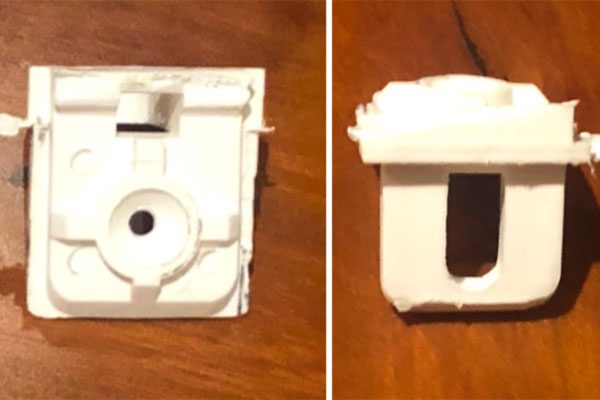

The part getting scanned (time required: a couple of minutes)

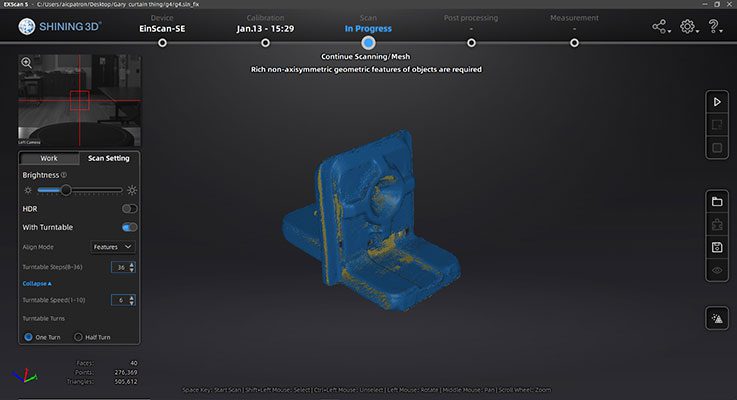

the 3D file generated by the scan (time required: less than a minute)

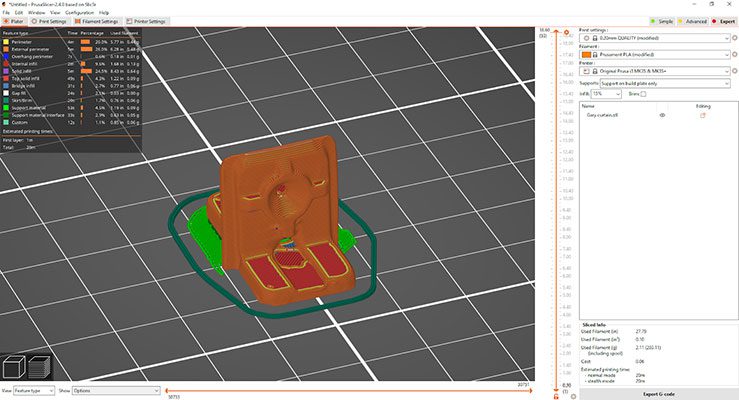

Once we had the file generated, Gary got certified on the 3D Prusa printers we have at the AIC. He took the file and prepared it to print.

The 3D model in the slicer

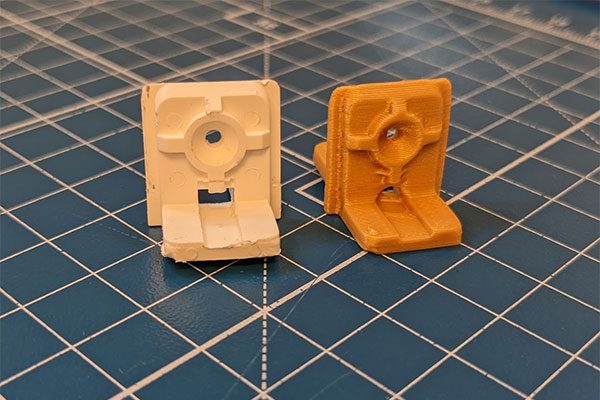

The printed part next to the original part

Final part installed on the rod